Published Dec 10, 2025

Characterising and understanding the detailed structure of materials at the atomic level is essential to designing thin-film electronic devices. This is typically achieved with advanced analytical and imaging techniques of the surface crystal structure.

However, a functional gap remained in the tools available to scientists and industry. While real-time diffraction techniques measure the material surface as it is being grown, the missing piece was a modelling software that provides full control over the key parameters. This modelling software had to predict the resulting patterns based on the physics governing the electron beam diffraction at the surface. The ability to model diffraction behaviour during growth enables faster optimization, better quality control, and ultimately more efficient manufacturing.

That gap inspired the new simulation software package developed by researchers at Te Herenga Waka – Victoria University of Wellington. This essential software is now licensed to US-based k-Space Associates, Inc., a global leader in thin-film metrology solutions.

The pathway from an industry aligned PhD project to a licensed commercial product illustrates how the combination of early commercial thinking, industry engagement, and researcher mentorship can accelerate the commercial impact from fundamental science.

From research to real-world solution

The idea for the software began with an industry aligned research challenge led by Dr Franck Natali, an Associate Professor in the School of Chemical and Physical Sciences. Franck has a background in researching epitaxial thin films - ultra-thin layers of crystalline material that form the foundation of modern semiconductor devices. Drawing on his experience, he formulates research projects that have real-world applications - one being, designing a missing piece of the materials development toolkit.

A widely used technique to monitor structural properties during fabrication is Reflection High-Energy Electron Diffraction (RHEED), which displays the electron diffraction patterns of crystals. But while the RHEED technique provides raw data about how the film is forming, there is no efficient way to interpret those patterns as it’s being grown to assess whether it has the required properties.

Guided by this industry need, Franck started forming a solution with his PhD student, Dr Jay Chan. Funded by a Marsden-funded research project, Jay began developing algorithms capable of simulating electron diffraction patterns, creating a predictive tool that could complement existing experimental data.

“I feel that it’s particularly crucial as a research leader and supervisor to provide effective and friendly advice and support to students in their early years of research study, " says Franck. “I and my former PhD student, Dr Jay Chan have developed a niche software tool, known as RHEED Simulation Software, that calculates the electron diffraction patterns of crystals. I recognised the use of this technology as a quality control measure when developing thin films in electronic devices, something that would be valuable for both industry and academic sectors. I mentored and supported Dr Chan to be part of this journey.”

Building commercial thinking into the research process

Franck and Jay worked closely with Wellington UniVentures’ commercialisation team to shape the project for real-world use. Early engagement with potential customers allowed the team to validate the software’s market relevance and refine its capabilities. As Franck already had deep industry connections, the pathway from prototype to product was unusually rapid.

“I presented the software programme and engaged directly with industrial R&D experts and companies to direct and accelerate through milestones our development phase. It took less than a year to go from early discussions to presenting a working prototype to companies,” notes Franck. “We collaborated directly with industry specialists, integrated their feedback into our development milestones, and ensured the final product aligned with what industry actually needed.”

The software has developed into a robust, research-grade simulation tool capable of calculating electron diffraction patterns for a wide range of crystalline materials. Rather than forming a spin-out company, the team implemented a licensing approach with UniVentures guidance, that allowed the technology to reach potential users quickly without requiring major capital investment.

In 2021, the software was licensed exclusively to k-Space Associates, Inc. Beta testing was carried out with select users before market launch. k-Space has since integrated the tool into its suite of characterisation technologies, deployed globally across research laboratories, semiconductor manufacturers, and academic institutions. 2025 marks another milestone in the product’s global rollout, as k-Space has successfully demonstrated the software, marketed as kSA RHEEDSim, at two international conferences.

“We are already seeing success with kSA RHEEDSim”, says Darryl Barlett, CEO of k-Space Associates. “We market RHEEDSim as both a standalone product and an integrated capability within our kSA 400 analytical RHEED system. We will continue to develop the technology, with a multi-user version for labs and classrooms launched this year. Several universities have already purchased kSA RHEEDSim, and are using it to help with their research and to educate students in materials science.”

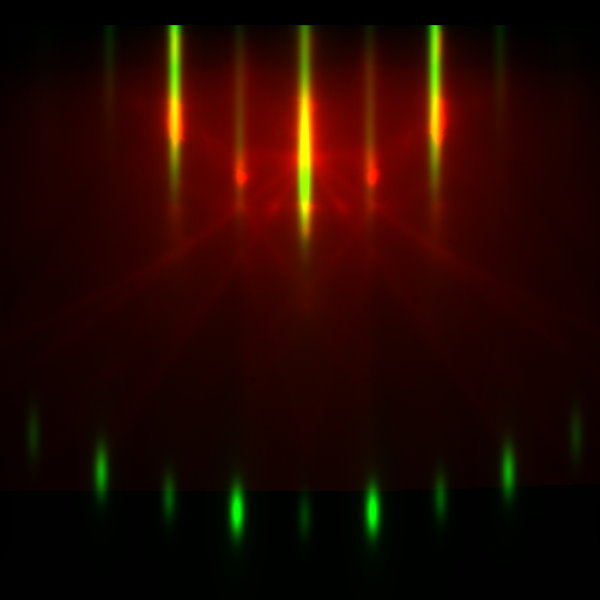

Users can compare simulated and experimental RHEED images. This example shows simulated (green) and experimental (red) data overlaid for MgO cut along 001 plane.

Users can compare simulated and experimental RHEED images. This example shows simulated (green) and experimental (red) data overlaid for MgO cut along 001 plane.

Lessons in innovation and impact

The project is a case study in how early commercial awareness, strong mentorship, and collaborative engagement can transform a piece of fundamental research into a product with real industry value.

“One of the most important lessons is that we often work on research with huge relevance to industry, but we don’t always realise it. Engaging with companies early, understanding their needs, and validating your ideas with them can make the difference between a project that stays in the lab and one that changes how people work”, advises Franck. “Talk to people at conferences, visit the industry stands, ask questions. The more you understand the problems companies are trying to solve, the more likely you are to create something that can make a difference. This project shows how fundamental science, when guided by industry insight and commercial support, can lead directly to practical solutions. That’s the kind of impact we want to keep creating.”

Get in touch with us to find out more: